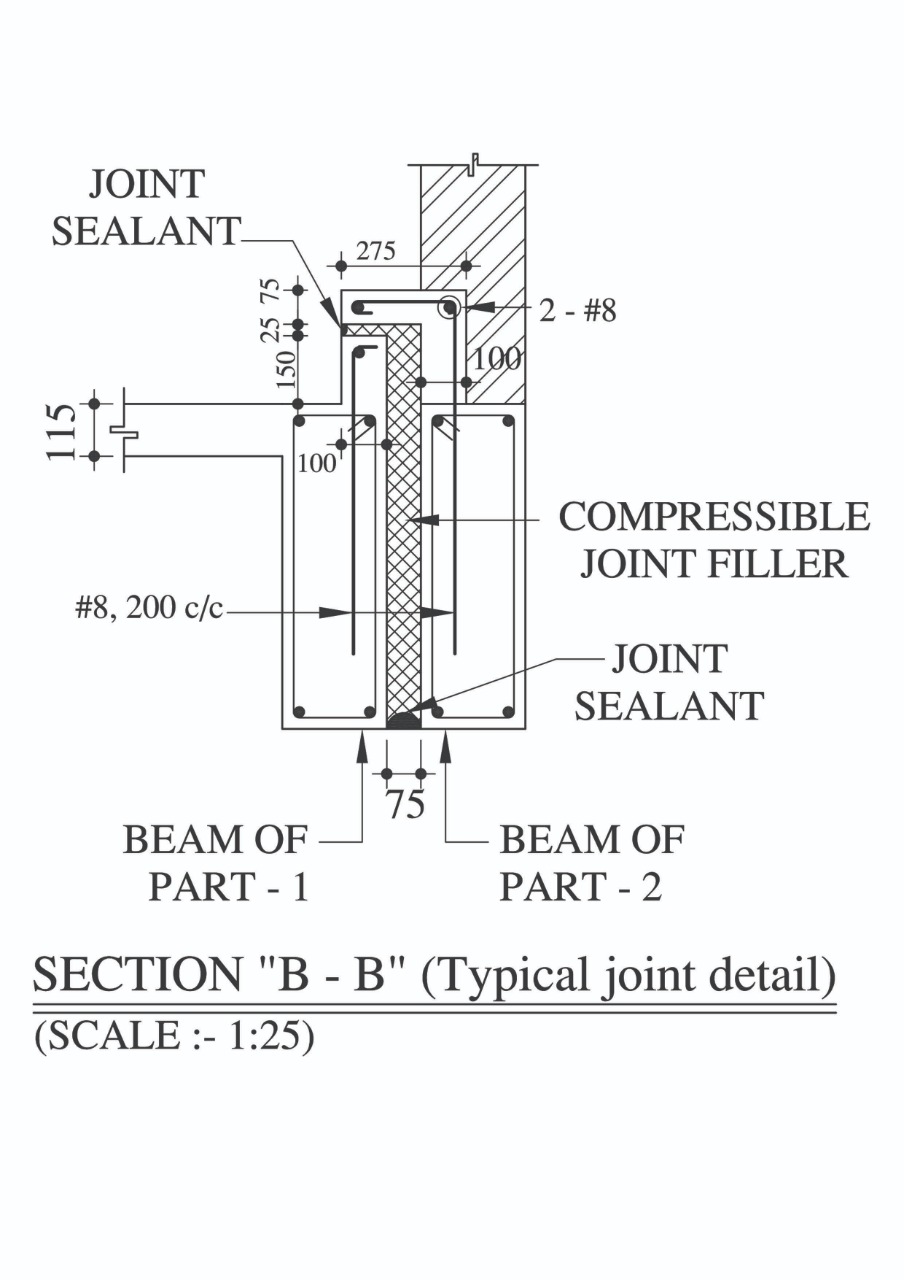

The construction of buildings, runways and roads, involves the casting of concrete in slab form, and various types of joints such as Expansion Joints, Construction Joints, Dummy Contraction Joints, etc. are encountered. These joints must be adequately and properly sealed to prevent seepage of surface water through the joints. STP’s Shalitex Joint Filling Boards and Sealing Compound System in the answer.

A) EXPANSION JOINTS

In the casting of slabs, provision must be made to accommodate the expansion and contraction which occurs with seasonal in temperatures. In tropical countries these variations are considerable. It is of utmost importance to use correct joint filling and sealing compounds to preserve the life and evenness of surface and to prevent water seepage.

a) Permits free movement of the concrete slabs by contracting when the slabs expand and expanding when the slab contract, thus still keeping the space between the slabs filled completely.

b) Provides a waterproof seal which will always prevent seepage of surface water downwards.

c) Resists entry of foreign matter into the joint space, thereby avoiding its obstruction to the free movement of slabs during expansion and thus preventing damage to the slab.

The materials used for filling and sealing expansion joints must be compressible, resilient and non-extrudible; as well as completely waterproof and rot proof.

Shalitex Expansion Joint Filler Boards and Shalitex Sealing Compounds are tested under rigid quality control for all these properties as specified in the relevant I.S. Specifications.

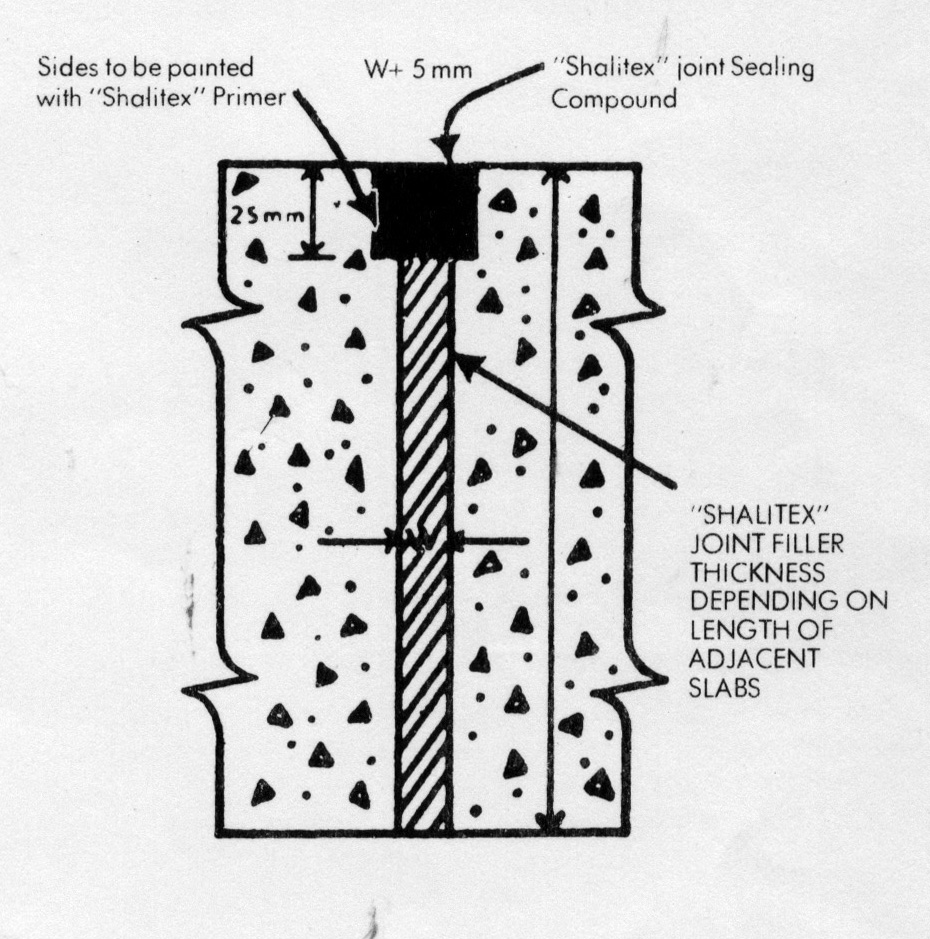

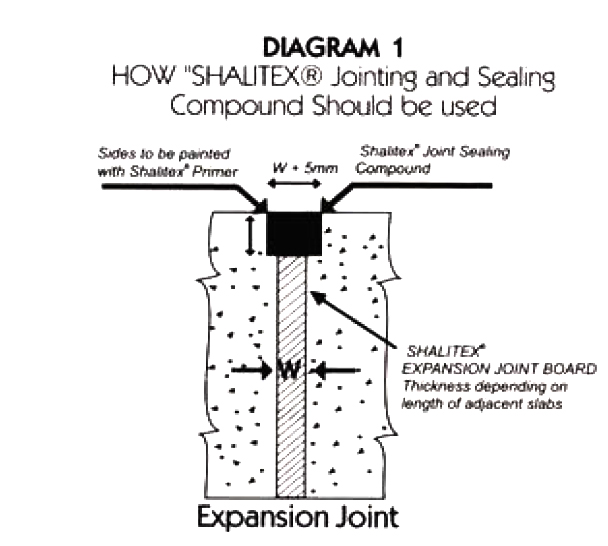

Procedure for filling expansion joints:

i) Clean the joints free of all loose concrete, dirt, dust and grit, preferably by air blowing.

ii) Apply a coat of appropriate Shalitex or Shalijet Primer by brush or by spraying and allow it to dry thoroughly. Primers are inflammable and should not be placed near a naked flame.

iii) Fill the gap with Shalitex Performed Expansion Joint Filler Boards (conforming to IS: 1838-1961) of the appropriate thickness leaving a gap of 25 mm height at the top of joint.

iv) Heat appropriate Shalitex or Shalijet Sealing Compound (conforming to IS: 1838-1961) of its specified working. Temperature and pour into the gap left at the top of the joint filling board, filling the gap completely and slightly pouring over the slab.

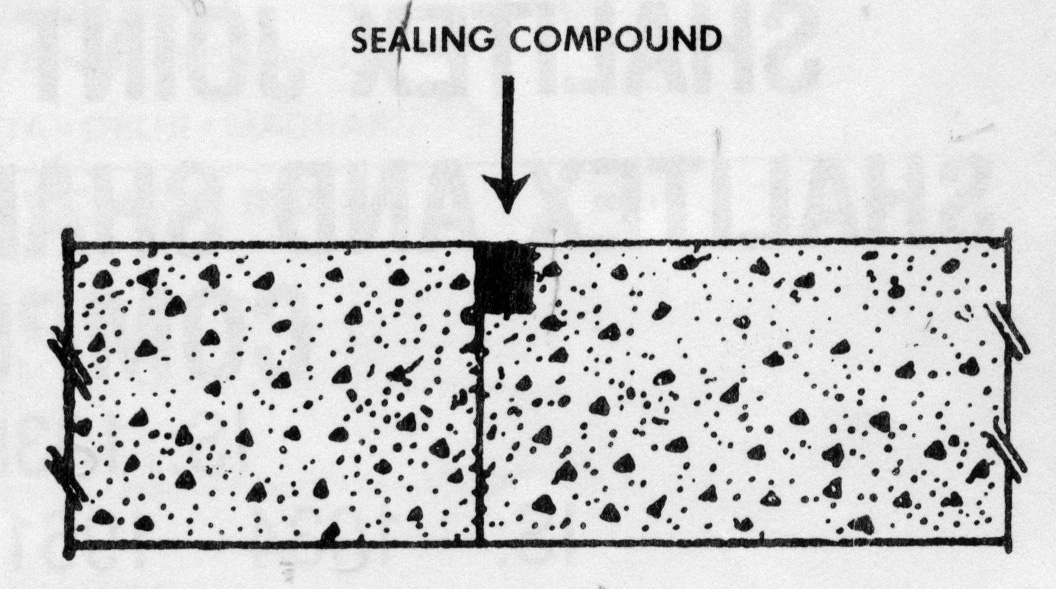

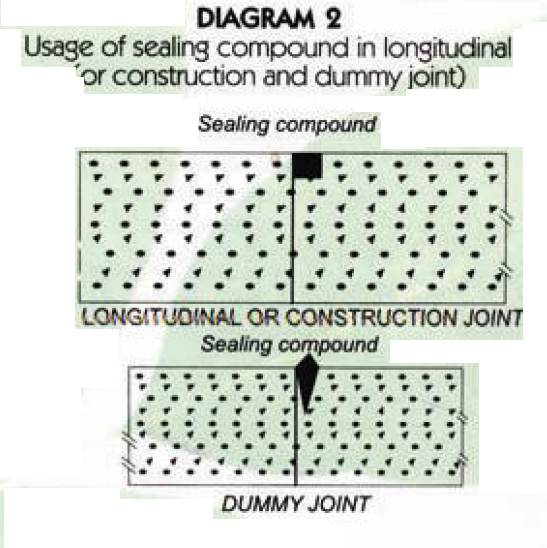

B) CONSTRUCTION JOINTS

In concrete pavements, roads and runways, it is not possible to lay, the slab of entire length and width at a time, thus resulting in joints between the slabs layer at two different times. These joints are highly susceptible to water seepage. It is therefore customary to provide construction joints in order to facilitate the placing of concrete. These are plain but joints with a sealing groove 18 mm wide at the top of joint.

Procedure for filling construction joint:

i) Clean the joints free of all loose concrete, dirt, dust and grit, preferably by air blowing.

ii) Apply a coat of appropriate Shalitex or Shalijet Primer by brush or by spraying and allow it to dry thoroughly.

iii) Heat appropriate Shalitex or Shalijet Sealing Compound (conforming to IS: 1834-1961) to its specified working temperature and pour into the gap, filling the gap completely and slightly pouring over the slab.

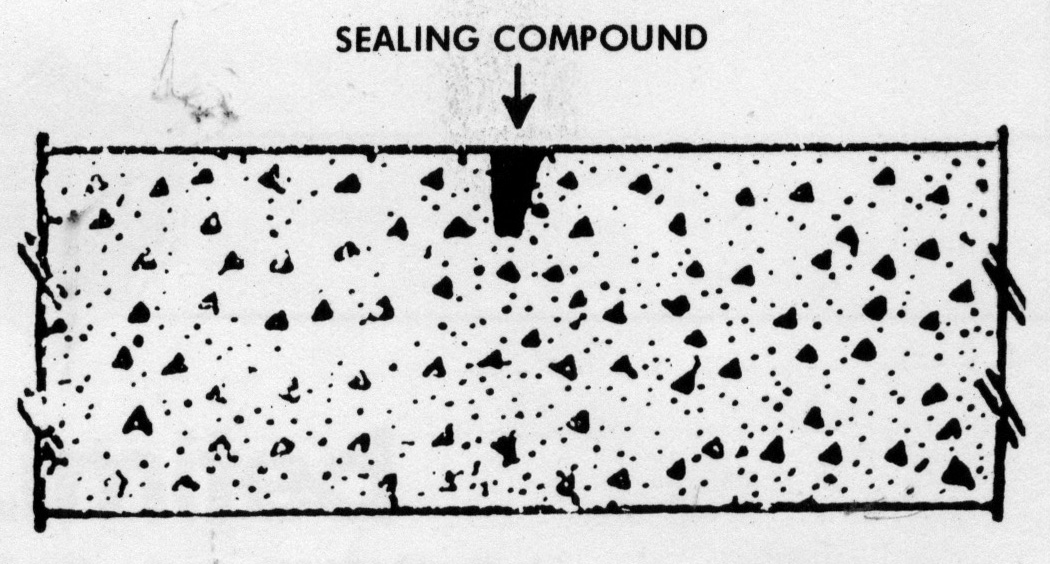

C) DUMMY CONTRACTION JOINTS

These are provided longitudinally and transversely at regular intervals in order to control the cracking which results from the contraction of the concrete on setting. Such joints are normally 18 mm in width extending to a depth equals to one third of the slab thickness.

Procedure for filling dummy construction joint:

i) Clean the joints free of all loose concrete, dirt, dust and grit, preferably by air blowing.

ii) Apply a coat of appropriate Shalitex or Shalijet Primer by brush or by spraying and allow it to dry thoroughly.

iii) Heat appropriate Shalitex and Shalijet Sealing Compound (conforming to IS: 1834-1961) to its specified working temperature and pour into the gap, filling the gap completely and slightly pouring over the slab.

Shalitex Expansion Joint Fillers (IS: 1838-1961).

Shalitex Expansion Joint Filler is a fiber board impregnated with bituminous materials to render it durable and rot proof. It is compression is released, thereby ensuring that no free space develops in the expansion joint. Used in-between concrete slabs in roads, runways, buildings and bridge decks.

Thickness available: 8-9 mm, 12 mm, 18 mm, 25 mm, Supplied in standard dimension of 4’ X 4’ (1.22 m x 1.22 m) = 16 Sq. ft. (1.486 Sq. m)

Shalitex Sealing Compound (IS: 1834/1961 Grade A)

Shalitex Sealing Compound is an ideal Hot Joint Sealing Compound. It complies with the requirnments of Grade A Sealing Compound, of IS: 1834/1961. It has a working temperature of 175° – 185° C (345°F) and a density of 1020 kg. per cubic metre.

Before applying Shaliex Sealing Compou, the sides of the joint should be sprayed or brushed with Shalitex Primer. The primer should be allowed 24 hours to dry out thoroughly before the Sealing Compound is poured into the joint.

Shalijet Sealing Compound (IS: 1834/1961 Grade B)

Shalijet Sealing Compound is applied over Shalitex Joint Filler, and is used on airfield runways, from where aircraft fly. These jointing materials are unaffected by fuel spillage and heat from jet exhausts.

Shalitex Sealing Compound is also used for joints in garages, filling stations, etc. where there is spillage of petrol, oil or grease. It complies with the requirement of Grade B Sealing Compound of IS: 1834/1961 and has a working temperature of 155° – 165°C (310-330°F) and a density of 1200 kg. Per cubic meter. Before applying Shalijet Sealing Compound, the side of the joint should be sprayed or brushed with Shalijet Primer to ensure good adhesion. The premier should be allowed to dry thoroughly before the Sealing Compound is poured into the joint.

Packing:

- SHALITEX SEALING COMPOUND, IS: 1834-1961, Grade A

18 kg. Non-returnable steel drums.

143 kg. Non-returnable steel drums.

- SHALIJET SEALING COMPOUND, IS: 1834-1961, Grade B

20 kg. Non-returnable steel drums.

200 kg. Non-returnable steel drums.

- SHALITEX PRIMER AND SHALIJET PRIMER

20 lit. Non-returnable steel drums.

200 lit. Non-returnable steel drums.

Consumption:

Joint Sealing Compound required per 100 meters of running joint in kg. Per 25 mm depth for various thickness:

9.5 mm thickness 29.5 kg.

12.0 mm thickness 40.2 kg.

18.0 mm thickness 59.0 kg.

25.0 mm thickness 82.0 kg.

An allowance of 5% should be made for wastage during application.

Requirement of primer should be based on a consumption of 78 running meters per liter for 25 mm depth of joint.

Joint Fillers & Sealing Compounds

Description

The normal practice in runways, bridge, building and road construction is to provide expansion joint & cutting between cutting slabs of reinforced concrete at designed intervals, and at intersections with other constructions. These joint fillers are then covered with sealing compounds; STP offers the complete range of products in this area.

Shalitex ® Expansion Joint Boards

Conforming to IS: 1838 (Part-1) 1983 Consist of a fiber board, impregnated with bituminous material to make it durable and waterproof

Purpose

- To permit free movement of the concrete slabs during expansion and contraction

- To provide a waterproof seal

- To resist entry of foreign matter into the Joint space.

Physical Characteristics

- Consist of a soft fiber board impregnated with bituminous materials.

- Compressible

- Possesses a high degree of recovery, once compression is relaxed

- None extruding

- Available in thickness of 12 mm, 18 mm and 25 mm

Shalitex ® Sealing Compound

Conforming to IS: 1834-1984, Grade A

Physical Characteristics / Purpose

- Displays good adhesion towards concrete

- Has the ability to withstand expansion without cracking

- Low susceptibility to flow during hot weather conditions

- Offers resistance to ingress of foreign substance

Packaging

Shalitex ® Expansion Joint Boards are supplied as 4’x4’ of 4’x2’ sheets as per requirements.

However it can be supplied in crates on special request.

Shalitex ® Sealing Compound

Conforming to IS: 1834-1984, Grade A

Physical Characteristics / Purpose

- Displays good adhesion towards concrete

- Has the ability to withstand expansion without cracking.

- Low susceptibility to flow during hot weather conditions

- Has plasticity.

- Offers resistance to ingress of foreign substance

Application Methodology

(1) Before applying SHALITEX ® SEALING COMPOUND the sides of the joint should be cleaned of dust, etc. by jet or dry air followed by thorough drying.

(2) The sides should be sprayed or brushed with SHALITEX ® PRIMER.

(3) Once the Primer has dried completely, SHALITEX ® SEALING COMPOUND is poured into the joint. The working temperature is 170°C – 185°C. Do not overheat.

(4) During the pouring process, spillage can be minimized if wooden boards are laid on each side of the joint. The pouring should be done from a can with extended spout.

(5) The quantity of SHALITEX ® SEALING COMPOUND required per 100 meters of running joint of 25 mm depth, for various thickness are:

12.0 mm thickness 36kg

18.0 mm thickness 54kg

25.0 mm thickness 75kg

(An allowance of 5% should be made for wastage during application)

Packaging

Available in 18 kg & 200 kg drums

Shalitex ® Sealing Compound

Conforming to IS: 1834-1984, Grade B

In construction of runways (whereon jet aero planes taxi) sealing compound which are unaffected by fuel spillage and are less likely to be damaged by the heat from jet exhaust are required, SHALIJET ® SEALING COMPOUND has been developed for this purpose. It can also be used for sealing joints in garages filling stations and other places, where there is a spillage of petrol, oil or grease.

Application Methodology

(1) Sides of the joints should be cleaned of dust, etc. by a jet of dry air and thoroughly dried.

(2) The joints should be sprayed or brushed with SHALIJET ® PRIMER to ensure good adhesion.

(3) Requirements of primer should be based on a consumption of 78 running meter per liter, for 25 mm depth of joint.

(4) Once the Primer has dried completely, SHALIJET ® SEALING COMPOUND is poured into the joint. The working temperature is 155°C – 165°C, The method of heating, and the pouring technique are same as that used for SHALITEX ® SEALING COMPOUND.

(5) The quantity of SHALITEX ® SEALING COMPOUND required per 100 meters of running joint of 25 mm depth, for various thickness are as under:

12.0 mm thickness 44kg

18.0 mm thickness 65kg

25.0 mm thickness 92kg

(An allowance of 5% should be made for wastage during application)

Packaging

Available in 26 kg & 200 kg drums

SHALITEX ® SEALING COMPOUND-CL

Conforming to IS: 13143: 1991, has been developed for use in canal linings involving the following

- Cast-in-situ cement concrete lining

- Precast cement concrete lining

- Flagstone paving

Packaging

Available in 200 kg drums.

Precaution

- Primers are inflammable – hence, should not be placed near or exposed to naked flames.

- Keep Primer container closed when not in use.